Biomass Gasification

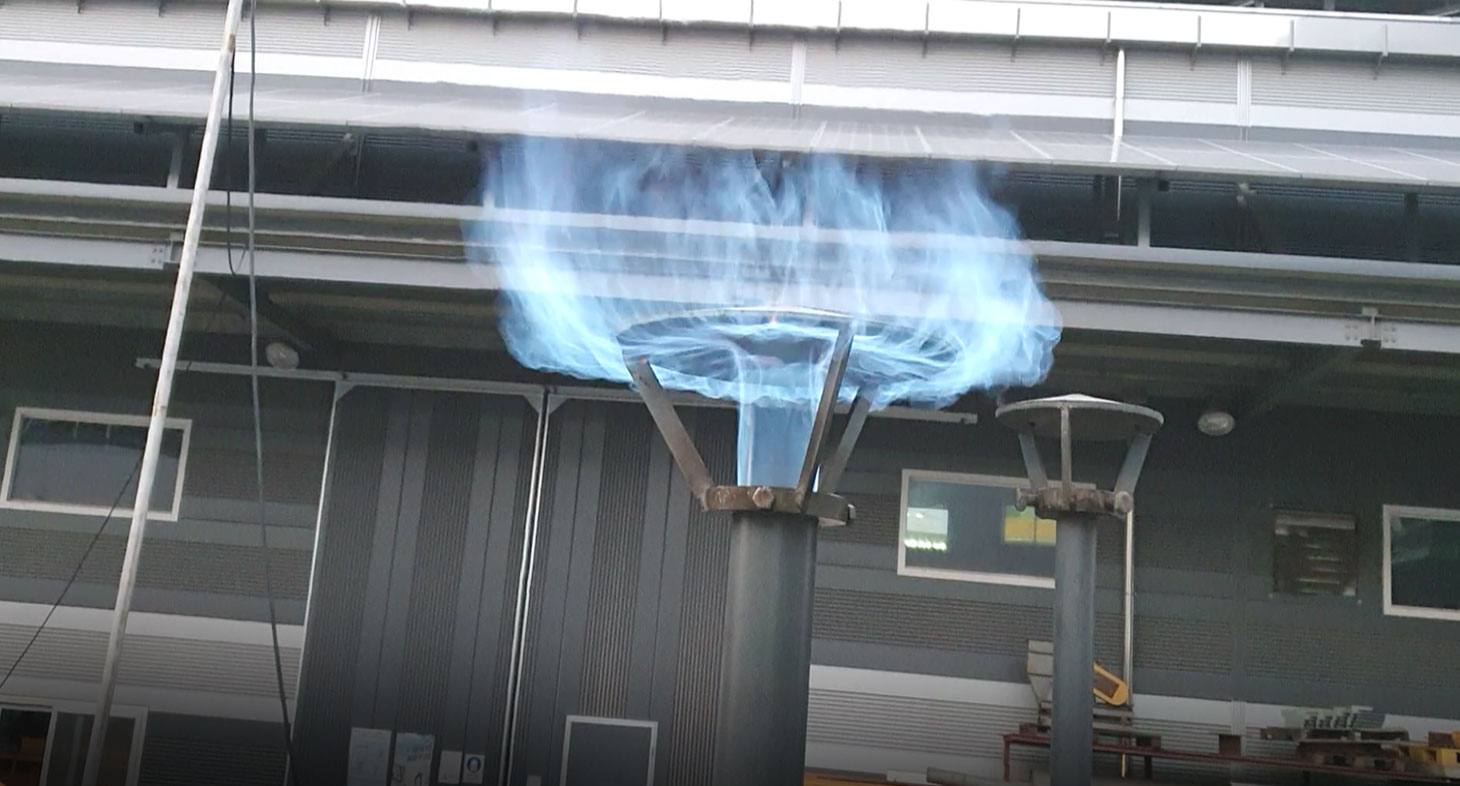

Sun Brand Industrial’s gasification equipment is a system that induces incomplete combustion by supplying a limited amount of oxidizer in oxygen. Through the drying, pyrolysis, and gasification processes, combustible gases such as CO and H2 are generated and utilized as heat sources. The equipment addresses various issues caused by the entry of by-products and clinkers generated during the direct combustion of biomass in boilers. Utilizing such combustible gases generated through gasification allows for solving problems associated with the entry of residues and clinkers into the boiler during the direct combustion of biomass. Therefore, replacing the burners of existing diesel and gas boilers with biomass gasification equipment can lead to significant fuel cost savings.

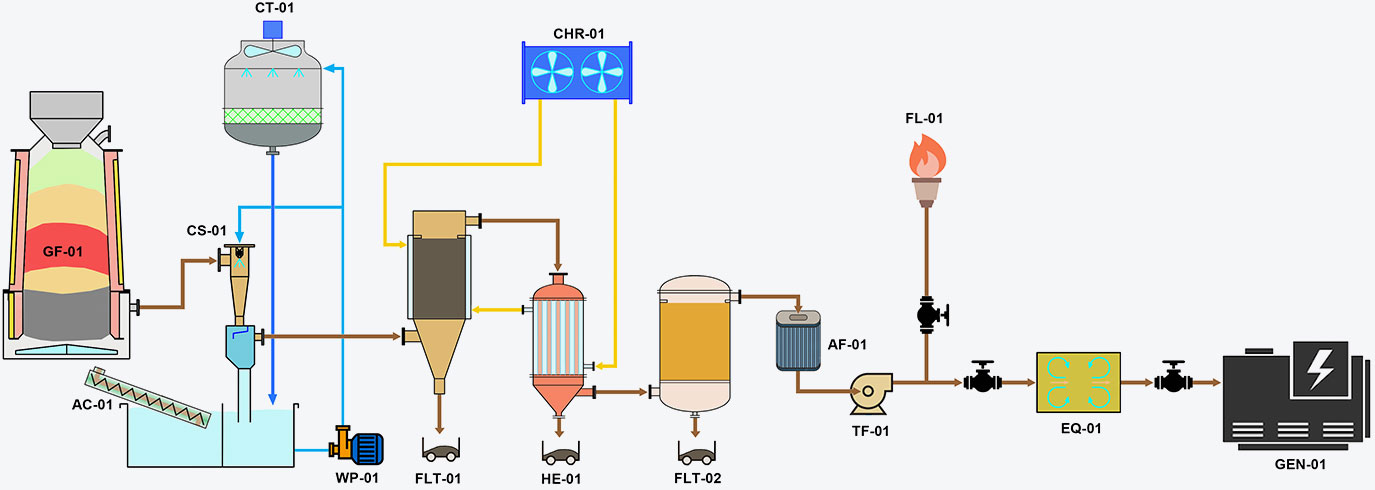

System Layout

Features

-

01

01Various raw materials with different properties such as fine woody debris and wood can be utilized

-

02

02Applicable to combustion devices ranging from 500,000 Kcal to 2.5 million Kcal

-

03

03Due to the characteristics of the burner using combustible gas, only a small area is required

-

04

04Fuel costs can be reduced compared to burners in diesel and gas boilers

-

05

05Can address various problems caused by residues and clinkers generated during biomass combustion

Gasification Equipment

Gasification Equipment

Gasification Shape

Gasification Shape